Silicon carbide tubular membrane

Characteristics of silicon carbide tubular membrane

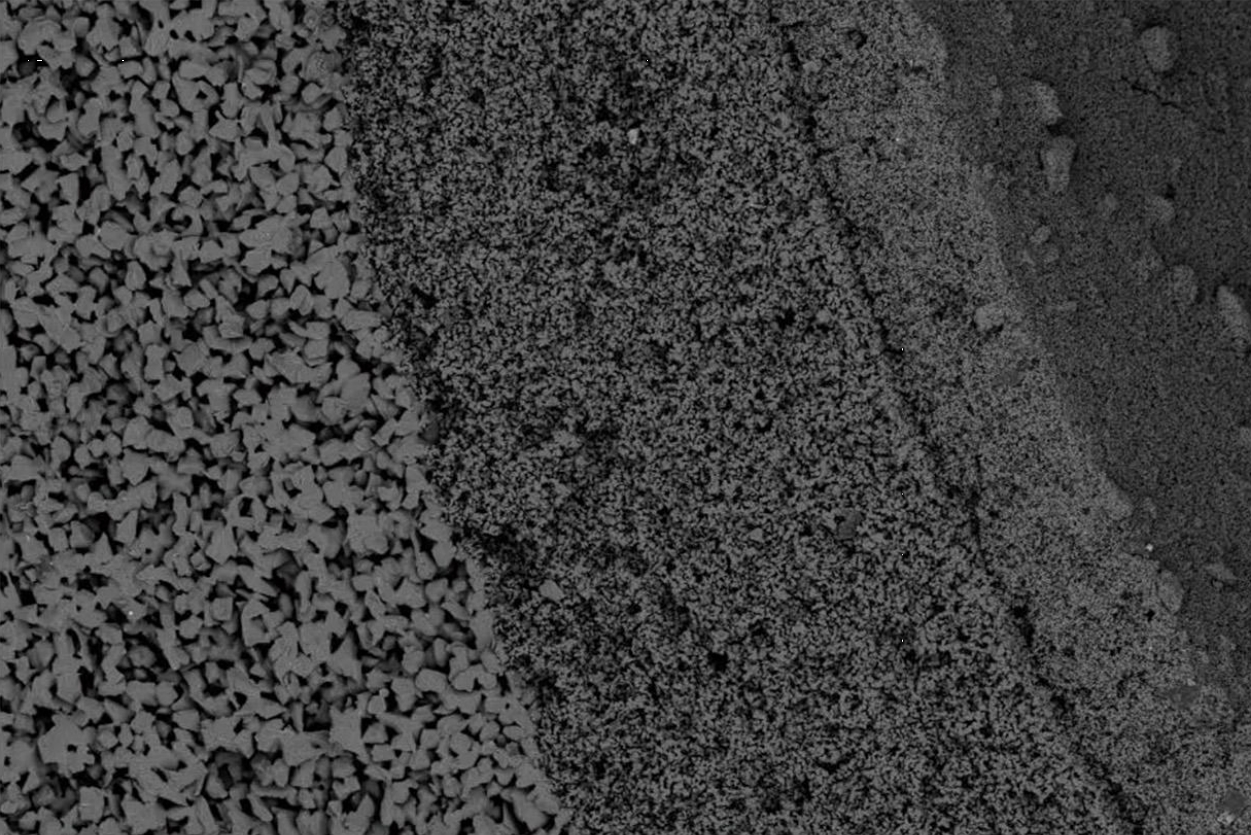

• The silicon carbide membrane is produced by recrystallization process, with a sintering temperature of 2400 ℃. During the sintering process, the sintering neck between the silicon carbide aggregates undergoes a phase transition from solid to gas to solid, with an opening rate of over 45%. The formed filter channel has strong connectivity, coupled with the inherent hydrophilicity of the silicon carbide material (contact angle only 0.3 °), resulting in a pure water flux of up to 3200LMH, and is hydrophilic and oleophobic.

• The isoelectric point of the silicon carbide membrane is around pH 3, and the surface of the membrane can maintain being negatively charged over a wide pH range, improving its pollution resistance.

• Excellent chemical stability, capable of working in extreme environments (pH range 1-14); a variety of cleaning plans can be developed based on the characteristics of pollution factors; Oxidants are fully tolerant, including ozone and hydroxyl radicals.

Silicon carbide tubular membrane

Washing and concentration of nano powder

Oil-water separation (oilfield reinjection water, liquid hazardous waste regeneration)

Material separation

Solid liquid separation with high solid content (mine water, biological fermentation broth)

Solid liquid separation in harsh chemical environment (acid purification, nano powder catalyst recovery)