Application of Silicon Carbide Ceramic Membrane in Acid Liquid Purification

-JMFILTEC-

In the membrane separation industry, materials have always driven the iteration of membrane separation products and the development of their application technologies.

Silicon carbide is a recognized next-generation ceramic membrane separation material in the industry, with significant performance advantages such as high throughput, corrosion resistance, easy cleaning, and long service life.

Especially in the field of acidic liquid purification, the advantages of our silicon carbide ceramic membrane are undoubtedly evident.

The advantages of silicon carbide ceramic membranes come from

1.High throughput

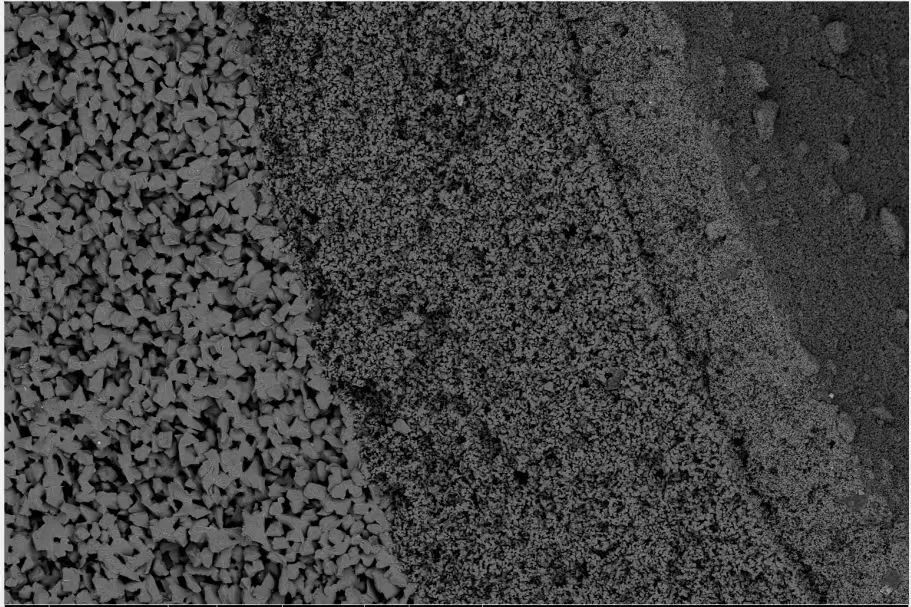

Silicon carbide ceramic membrane has its unique characteristic pore structure, composed of a 0.04μm compact microporous separation layer, a 0.5μm compact microporous sub separation layer, and an 8μm loose macroporous support body, results in low resistance during the filtration process.

At the same time, the silicon carbide ceramic membrane adopts the recrystallization sintering technology. During the sintering process, compared to the solid phase → liquid phase → solid phase process of the aluminum oxide material, the formation process of the fine nano powder sintering neck of silicon carbide ceramic membrane is solid phase → gas phase → solid phase. Because there is no liquid phase, there are few dead holes in the internal channels, and the three-dimensional structure is well connected, the porosity is up to more than 45%.

Secondly, silicon carbide materials have good hydrophilicity and a water contact angle of only 0.3 °.

2.Corrosion resistance

Silicon carbide material is an inert material that can even withstand the corrosion of hydrofluoric acid.

3.Easy to clean

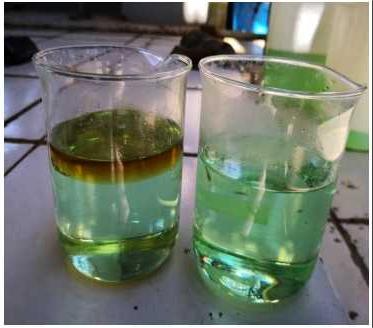

Firstly, the isoelectric point of silicon carbide nanoparticles is around pH 2.4, and within a wide pH range, the interface between the separation layer and the filtering medium can maintain a negative charge environment, forming a special anti fouling and oil blocking effect. Colloids, suspended solids, oil droplets and other substances can not easily attached to the membrane surface, and backwashing can easily "peel off" the membrane surface of colloids, suspended solids, oil droplets and other substances;

Secondly, the trapezoidal pore structure and the high porosity of the silicon carbide membrane (with fewer dead holes and good connectivity of the filtration channels) can enhance the backwashing effect;

And because the silicon carbide membrane has excellent corrosion resistance, the silicon carbide membrane system has a variety of optional cleaning solutions, which can use high concentration chemical agents for cleaning without worrying about chemical damage to the membrane layer.

4.Long lifespan

Strictly speaking, the service life of a membrane refers to the service life of the membrane separation layer. Silicon carbide ceramic membranes can ensure stable and long-lasting filtration performance due to their corrosion resistance and easy cleaning characteristics.

Partial cases display

Case One

Jiangsu company 5m ³/h Solid liquid separation project for mixed acid solution containing 10wt% nitric acid

Case 2

10m³/ h from a company in Yunnan Solid liquid separation project containing 15wt% hydrofluoric acid solution

Case Three

10m³/ h from a certain group oil-water separation project with 30wt% hydrochloric acid solution

Case Four

A certain enterprise in Shaoxing has a processing capacity of 5m ³/h, pH<2 material concentration project